In the fast‑moving world of logistics and conveyor systems, the choice of motor can feel trivial—after all, both gear motors and regular (direct‑drive) motors produce the same basic force. But in reality, the difference between these two types of motors is a critical decision point that shapes performance, maintenance, and cost in any material‑handling operation. This article explores why the distinction matters, when each type shines, and how future innovations may reshape the industry.

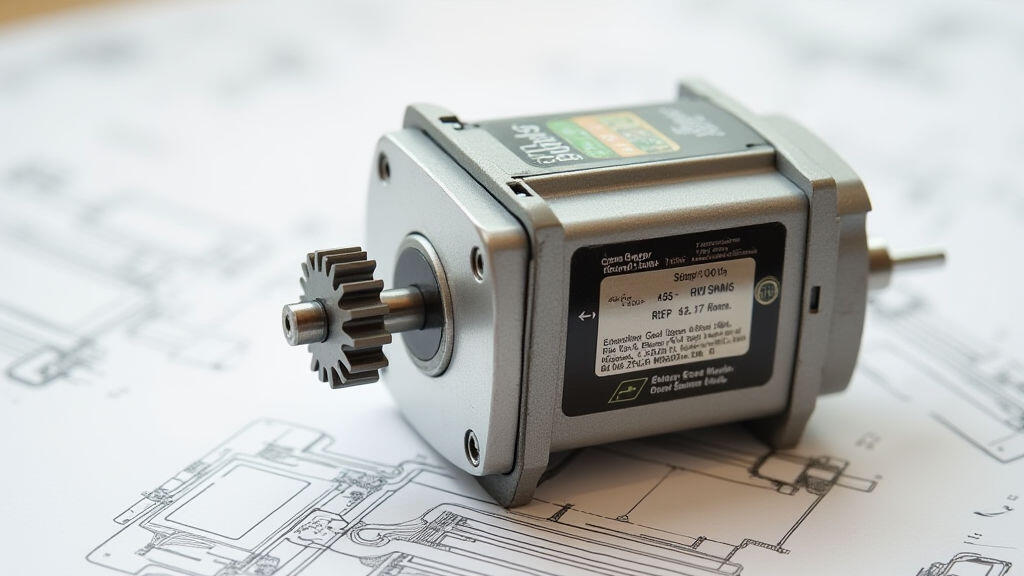

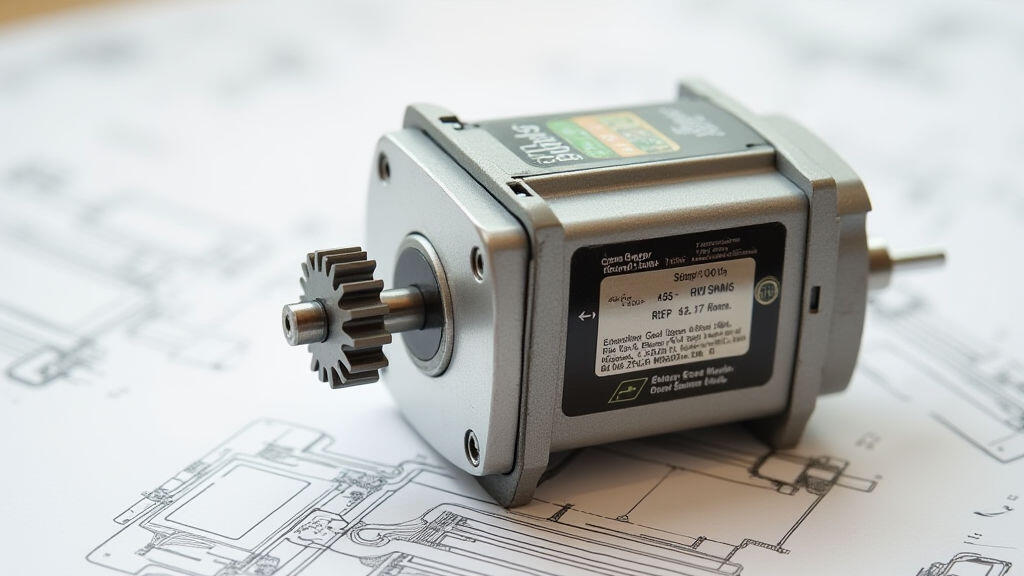

A gear motor is essentially a small DC motor with a gearbox attached. The gearbox reduces the high speed of the motor shaft and increases torque, allowing the motor to move heavy loads at slow speeds. In a conveyor application, a gear motor might turn a gearbox that drives a chain or belt at a fraction of its motor RPM.

Key features:

Regular motors—often referred to as direct‑drive motors—operate the conveyor belt or chain directly from the motor shaft, without an intermediate gearbox. They are typically larger because they need to generate enough torque at the shaft to move the load directly.

Key features:

When a conveyor must move massive items—think forklifts, pallets, or oversized goods—gear motors are the go‑to because they can pull heavy loads from a stationary start point. The gearbox allows the motor to stall or operate at low speeds while still maintaining enough torque to move the load. This is common in:

In systems that require steady, continuous motion—like food processing lines, pharmaceutical packaging lines, or airport baggage conveyors—a regular, direct‑drive motor offers superior performance. The direct‑drive design reduces backlash, vibration, and maintenance needs. Because the motor runs at the conveyor’s operating speed, it can be tuned for optimal efficiency, resulting in lower energy consumption over long operating periods.

Choosing between gear and direct‑drive motors involves balancing a few key factors:

A mid‑size snack‑food manufacturer recently upgraded its packaging line that uses a high‑speed conveyor to move trays from filling to sealing stations. The original system employed a gear motor that was difficult to keep lubricated due to the gearbox’s location in a dusty environment. After a year, the company experienced a 12% downtime due to gearbox wear.

They replaced the gear motor with a direct‑drive brushless DC motor, implemented with a soft‑start controller. Within six months, the line saw:

- 30% reduction in energy use due to higher efficiency.

- 90% decrease in maintenance visits, as the motor no longer had internal gears to wear out.

- Improved product throughput, attributed to smoother belt motion and reduced vibration.

Emerging technologies blur the line between gear motors and direct‑drive motors. Hybrid drives combine a compact motor with a low‑ratio gearbox for precise torque control, while intelligent drive systems use real‑time sensors to adjust torque and speed dynamically. In logistics, this translates to conveyors that adjust to the actual load weight, saving energy and improving safety.

Additionally, the rise of electric buses and autonomous material handling robots signals a shift toward smaller, high‑torque motors that can be easily swapped or re‑programmed—an advantage more associated with modern gear motors. Conversely, the demand for long‑running, low‑maintenance fleet conveyors in micro‑distribution centers favors direct‑drive solutions.

The choice between gear motors and regular (direct‑drive) motors is far from trivial in logistics and conveyor design. Gear motors offer the punch needed to start and move heavy loads, making them indispensable in high‑draft systems, but they incur higher maintenance and lower efficiency. Direct‑drive motors shine in continuous, high‑speed operations where smoothness, energy savings, and reduced upkeep are paramount.

As the industry moves toward smarter, more energy‑efficient systems, understanding these differences will become even more critical. Whether you’re selecting a motor for a new warehouse line or retrofitting an existing plant, a clear grasp of gear versus direct‑drive capabilities ensures that you invest in the right technology for both today’s needs and tomorrow’s challenges.

Leave A Reply

Your email address will not be published. Required fiels are marked